Product

Home Product

Home Product PIPING SYSTEM

HDPE

High-density polyethylene (HDPE) pipe systems are durable, mechanically strong, and highly impact resistant. It is the best pipe system with wide range of applicability, from water piping to chemical piping in the semiconductor process. KUPP produces and supplies pipe systems for various purposes such as water supply, firefighting, communications, gas, chemistry, agriculture, etc.

-

01

- Size Range

- 16 ~ 1200mm

-

02

- Temperature

- -50 ~ 60°C

-

03

- Welding Type

- Butt fusion, Electro fusion, Mechanical type, NIT type

-

04

- Pressure Rating

- 4 ~ 25 bar

Advantage

-

- Chemical Stability

- Free from corrosion caused by acids, alkalis, and salts. Also inhibits internal bacterial growth within the pipe.

-

- Corrosion Resistance

- No corrosion from seawater or wetlands, nor any erosion from stray electrical currents.

-

- Hygiene

- Guaranteed free of contaminants such as iron, ensuring the purity of the contents, making it an ideal solution for potable water supply.

-

- Impact Resistance

- Excellent resistance to external impact damage, resulting from PE’s inherent material toughness

-

- Flexibility

- Smooth internal surface minimizing frictional head loss, preventing pipe blockage.

-

- Cold Resistance

- Retention of physical and mechanical properties down to -80°C, ensuring immunity to pipe freezing and burst.

-

- Lightweight

- Easy handling and installation, weighing one-seventh the weight of steel piping.

-

- Abrasion Resistance

- Outstanding abrasion resistance, making the material suitable for mining slurry transportation and dredging line applications.

-

- Joint Compatibility

- Quick and flawless joining through various site-specific methods including compression fittings and heat fusion.

-

- Cost-Effectiveness

- Lower material costs compared to other pipe types, resulting in minimized maintenance and repair expenses.

Applications

-

Waterworks

Waterworks -

Firefighting

Firefighting -

Telecommunications

Telecommunications -

Gas

Gas -

Chemicals

Chemicals -

Agriculture

Agriculture

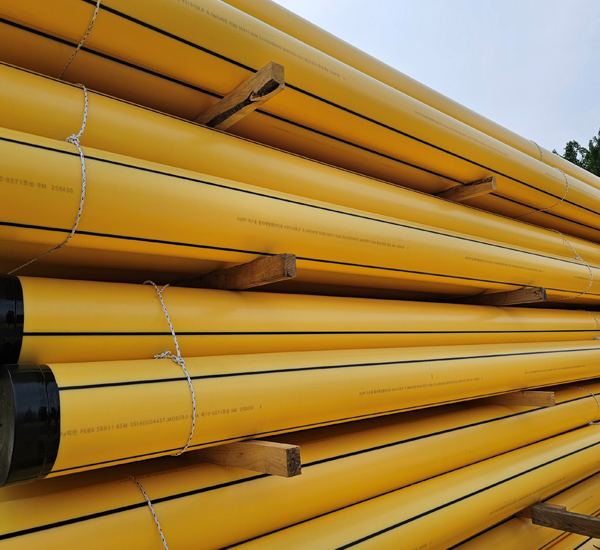

PIPES

Water Pipes

PE 100 HDPE

KUPP’s HDPE water pipes are manufactured from high-density polyethylene (HDPE) PE100, renowned for its excellent physical and chemical properties. They are resistant to corrosion and electrochemical degradation. The addition of carbon black further enhances UV and weather resistance. The HDPE raw material’s inherent hygiene is well-established, being frequently used for food containers and cutting boards. Consequently, KUPP’s HDPE pipes are ideally suited for a wide spectrum of applications—from potable water and beverages to piping in water-treatment facilities.

Go to the blog

Plant Piping

PE 100 (PERC)

PE 100 RC maintains the excellent Rapid Crack Propagation (RCP) performance of conventional PE 100 while significantly enhancing Slow Crack Growth (SCG) resistance. This mitigates long-term slow-crack failure caused by scratches during installation, thereby extending the pipe’s service life and reinforcing its abrasion resistance. It is ideally suited as an insertion pipe for trenchless installation methods, which are recently gaining popularity. Furthermore, its outstanding chemical resistance has resulted in increased utilization in demanding environments, such as semiconductor facilities and chemical wastewater piping.

Go to the blog

Firefighting Piping

PE 100 HDPE

The demand for HDPE fire-fighting piping is rapidly increasing, due to its superior resistance to corrosion, chemicals, and seismic activity compared to conventional steel pipes, alongside excellent cost-effectiveness and installation efficiency. KUPP, committed to delivering continuously advanced products, is broadening customer options with a diverse lineup, including HDPE and WEL fire-fighting piping systems.

Go to the blog

Multilayer Composite Pipe Series

WEL Multilayer Composite Pipe Series

KUPP’s WEL multilayer composite pipe series is a versatile HDPE piping solution available in various colors, designed for diverse applications, from water-treatment piping to utility lines within industrial plants. The WEL series combines the flexibility of HDPE with superior physical strength and is offered in optimized package configurations to ensure efficient installation. This powerful combination makes WEL the choice for public institutions, industrial plants, and other infrastructure sites. From water supply and plant utilities to fire-fighting systems, the WEL series establishes a new benchmark for HDPE piping solutions.

Go to the blog

Gas Pipes

PE Gas Pipes

KUPP’s PE gas pipes are extruded from high-performance polyethylene (PE), offering excellent physical properties, immunity to corrosion and electrolysis, and high ductility for convenient installation. We supply a comprehensive range of associated components, including PE fusion fittings, electrofusion (EF) fittings, TF connectors, and fusion equipment, all of which ensure high quality and safe installation. KUPP’s PE gas pipes are used in urban gas distribution networks, LNG and LPG group supply facilities, and auxiliary installations for offshore structures.

Go to the blog

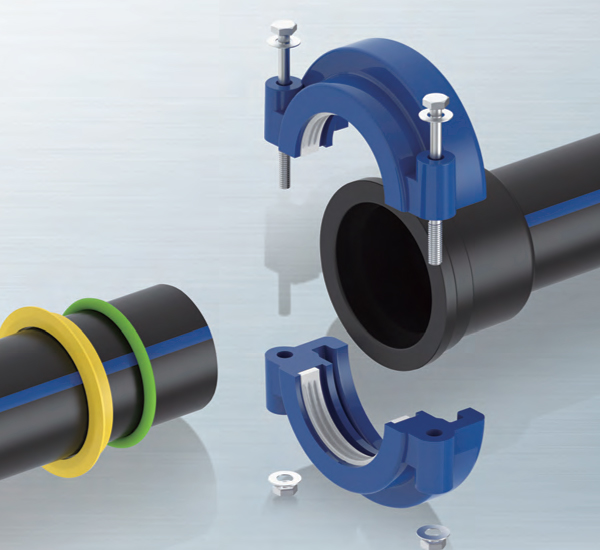

Branch Pipes

NIT-Type Branch Pipes

KUPP’s NIT-type PE water branch pipes feature adjustable holders that minimize expansion and contraction, facilitating convenient bolted installation and ensuring complete watertightness via rubber sealing rings. The polyacetal holders securely anchor the inlet pipe, with the adjustable design preventing material property changes(such as expansion and contraction) and ensuring a reliable PE water piping installation.

Go to the blog-

PE100/PERC

PE100/PERC -

WEL SERIES (Water/Firefighting/Plant)

WEL SERIES (Water/Firefighting/Plant) -

PE GAS PIPE

PE GAS PIPE -

PE INSULATED PIPE

PE INSULATED PIPE -

COD/ SCD TELECOMMUNICATION PIPE

COD/ SCD TELECOMMUNICATION PIPE -

RTP

RTP -

NIT PE PIPE

NIT PE PIPE -

FR-LSZH PE PIPE

FR-LSZH PE PIPE

Click the Icon to redirect to the blog.

FITTINGS

-

BUTT FUSION FITTINGS ( Water / Gas )

BUTT FUSION FITTINGS ( Water / Gas ) -

ELECTRO FUSION FITTINGS

ELECTRO FUSION FITTINGS -

COMPRESSION FITTINGS

COMPRESSION FITTINGS -

NIT FITTINGS

NIT FITTINGS -

PE BALL VALVE ( Water / Gas )

PE BALL VALVE ( Water / Gas ) -

SERIES 1 BALL VALVE

SERIES 1 BALL VALVE -

TAPPING SADDLE

TAPPING SADDLE -

UNIVERSAL SLIP REPAIR SOCKET

UNIVERSAL SLIP REPAIR SOCKET

Click the Icon to redirect to the data library.

WELDING EQUIPMENTS

-

BUTT FUSION WELDING MACHINE

BUTT FUSION WELDING MACHINE -

ELECTROFUSION WELDING MACHINE

ELECTROFUSION WELDING MACHINE -

SOCKET FUSION WELDING MACHINE

SOCKET FUSION WELDING MACHINE -

TOOLS

TOOLS