Product

Home Product

Home Product PIPING SYSTEM

PP-H (Polypropylene Homopolymer) PIPING SYSTEM

PPH Piping System manufactured by nucleated polypropylene homopolymer with high melt viscosity for extrusion. PPH has a high heat-stability and extraction stability. Also, system has High impact and stiffness balance, High Resistance to ageing, and Chemical resistance. Compared to other thermoplastic plastics, it has a service life up to 90℃ and can be used for a variety of purposes, including alkali, organic solvents, and pure water, and is used in a wide range of plants such as semiconductor processing, various chemical piping, steelmaking, fresh water, acid, and exhaust lines.

-

01

- Size Range

- 25 ~ 315mm

-

02

- Temperature

- -0 ~ 90°C

-

03

- Welding type

- Butt type, Socket type

-

04

- Pressure rating

- 10 bar

Advantage

-

- Thermal Resistance

- Service range 0 °C - 90 °C

-

- Low Surface Roughness

- High flow coefcients (extremely smooth internal walls) Pressure drop constant over time Low risk of stoppages due to scaling Reduced transfer of material to the transported fluid

-

- Chemical Resistance

- Suitable for conveying chemicals (excellent results with Salts and highly alkaline solutions)

-

- Abrasion Resistance

- Extremely low operating costs due to its long service life

-

- Insulation

- Non-conductive (immune to galvanic corrosion) No condensation problems Minimum heat loss

-

- Non-toxic

- Physiologically safe Environmental compatibility

-

- Easy Jointing

- Low installation costs Possible connection with many accessories and appliances

-

- Low Specific Weight

- Low transport costs Ease of handling and installation

Applications

-

Chemicals

Chemicals -

Semiconductor

Semiconductor -

Secondary battery

Secondary battery -

Medicine/Pharmaceutical

Medicine/Pharmaceutical -

Water treatment

Water treatment

PIPES

Click the Icon to redirect to the blog.

FITTINGS

Click the Icon to redirect to the data library.

VALVES

Click the Icon to redirect to the data library.

WELDING EQUIPMENTS

-

BUTT FUSION FITTINGS

BUTT FUSION FITTINGS -

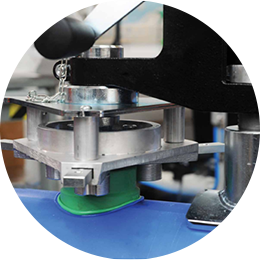

SOCKET WELDING MACHINE

SOCKET WELDING MACHINE -

SADDLE WELDING MACHINE

SADDLE WELDING MACHINE